- Home

- Applications

- Liquid

Packaging Machinery for Liquid

We offer custom solutions of premade pouch filling and sealing machines for liquid and paste packaging

Liquid packaging is a commonly used application, and our machines have undergone rigorous moisture-resistant testing. Constructed from durable 316 stainless steel, our equipment is resistant to mild corrosive liquids, ensuring long-term efficient operation.

We offer various solutions to meet your needs. In addition to handling neutral, high-flow liquids, we are also skilled in packaging viscous liquids, highly corrosive liquids, and small particle liquids.

Our packaging machines are compatible with four-side seal bags, stand-up bags, and spout bags. When selecting the right model, consider factors such as the bag size for your smallest and largest product weights, packaging speed, and other specifications. You can choose the product that best meets your needs.

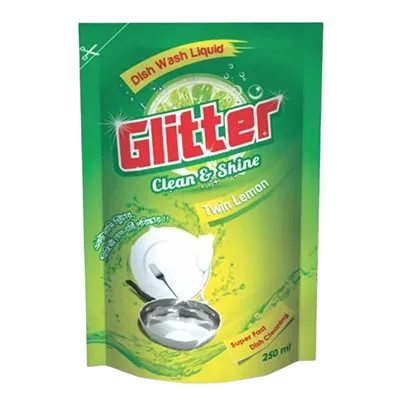

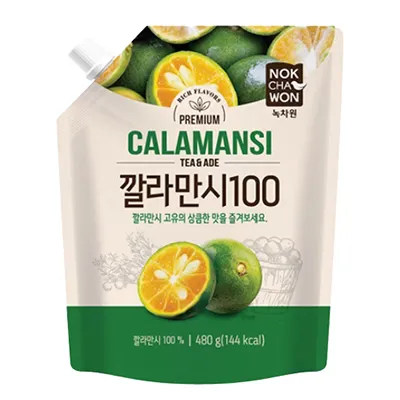

Suitable materials include: Dishwashing detergent, Shower gel and shampoo, Laundry detergent, Fabric softener, Oil, Drinks and more

Four side seal bag

Four side seal bag Stand-up bag

Stand-up bag Spout pouch

Spout pouchThe liquid filling process includes several key steps: preparation, container cleaning, material preparation, filling operation, sealing, packaging, and quality inspection.

The filling machine is a material feeding system that can operate independently or be linked with other equipment.

There are four main types of liquid filling machines:

Liquid filling machines can handle a wide range of liquids, from thin solutions to highly viscous substances, including beverages, juices, detergents, dish soap, laundry detergent, body wash, shampoo, sauces, tomato sauce, mayonnaise, soups, oils, and more.

Operators are responsible for sorting packaging materials (if needed), cleaning and lubricating the equipment, and clearing any blockages. They monitor the machine's operation and perform maintenance or report issues as necessary. Operators must ensure that the packaged products meet safety and quality standards.

The production speed of packaging machines varies. For example, small machines can produce 30 to 60 bags per minute, while high-speed models can exceed this range, reaching 80 to 100 bags per minute (commonly used with vacuum machines).

Liquid filling machines are versatile and can accommodate various container sizes and shapes. Adjustable settings and interchangeable parts enable quick and easy switching between different container types, improving production flexibility.

Give us a call today to find out what we have to offer.